The Call of the Open Sidewalk

From a place slightly to the side of the more popular path

[

Home

|

About

|

RSS

|

ATOM

|

Archives: 2013

2012

2011

2010]

Fri, 01 Oct 2010

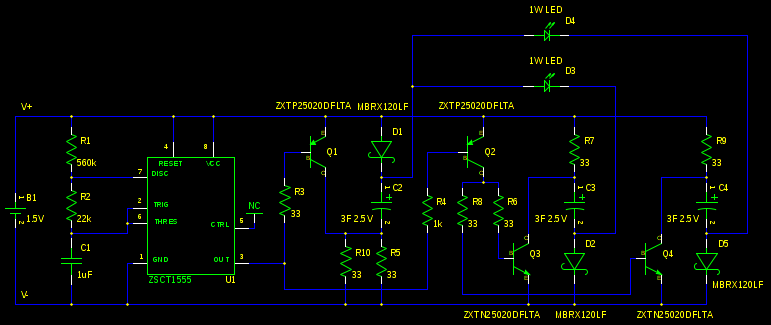

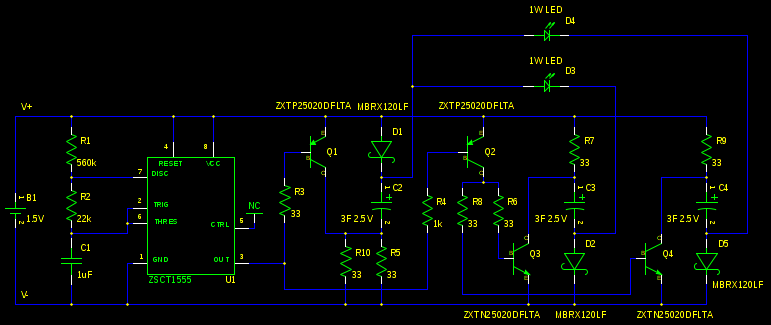

In a previous

post I talked about a prototype 1.5V powered LED flasher capable

of producing high pulse currents. The trick was to use supercapacitors

and pulse transistors in a voltage tripler arrangement. Here is how I

expanded the idea to produce a circuit that would flash two high power

LEDs at once:

This is more or less the same thing as described in the previous

post. C4 and associated components just provide another branch for the

extra LED. The common branch through C2 needs twice the charging

current so R10 was added. I spent some time exploring the idea of

using two supercaps with low internal resistance and then using 1 ohm

resistors to limit the current through the two LEDs. Unfortunately

very small differences in forward voltage caused great differences in

LED brightness. I then said the heck with it and

more or less duplicated the circuit resulting in the use of four

supercaps. That would not fit in the available board area. The three

supercap solution was the compromise. I couldn't see any reason not to

keep using the low internal resistance supercaps (other than the

larger size) so the 1F (0.4 ohm) supercaps are now 3F (.09 ohm)

supercaps. This allowed the increase of the charging resistors from 22

to 33 ohms for more or less the same pulse current. The other 22 ohm

resistors were changed to 33 ohm just to eliminate the extra component

value.

In the previous post I claimed that there was something wrong with the

description of the timing components on the datasheet for the ZSCT1555

timer. I now withdraw my scurrilous accusation. The problem was with

my understanding of the non-ideal operation of the device at 1.5V. The

new values of R1, R2 and C1 result in flashes of 50ms at a rate of 1

per second. The capacitor is now a 1uF ceramic that fits on a 0805

footprint.

With a fresh battery this circuit produced pulses of about 0.4A

through each LED. When the battery is at 1V I would expect the current

to be about a quarter of that. The system will enter "infinite battery

life" mode with the battery at 0.83V. There is no reverse battery

protection here. Tests revealed that on a reverse battery the only

component that takes abuse is the 555 timer. I think the package

should be capable of dissipating the excess power. It did get pretty

hot. Because of the larger supercap value the system takes a

noticeable length of time to come up to full brightness when the

capacitors are uncharged. I consider that pretty cool. Unfortunately

the capacitors retain their charge quite well over time.

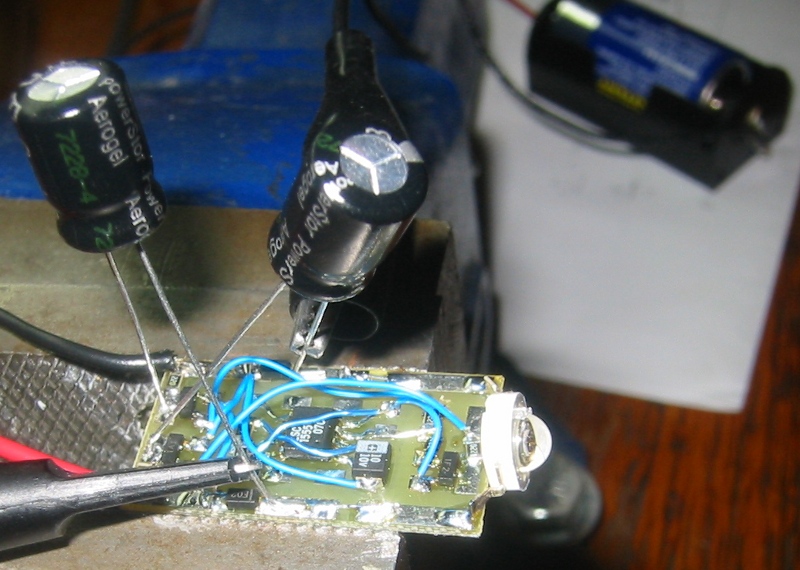

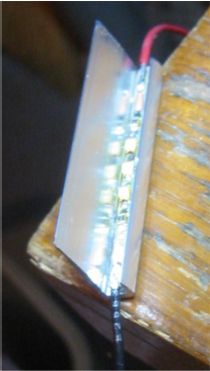

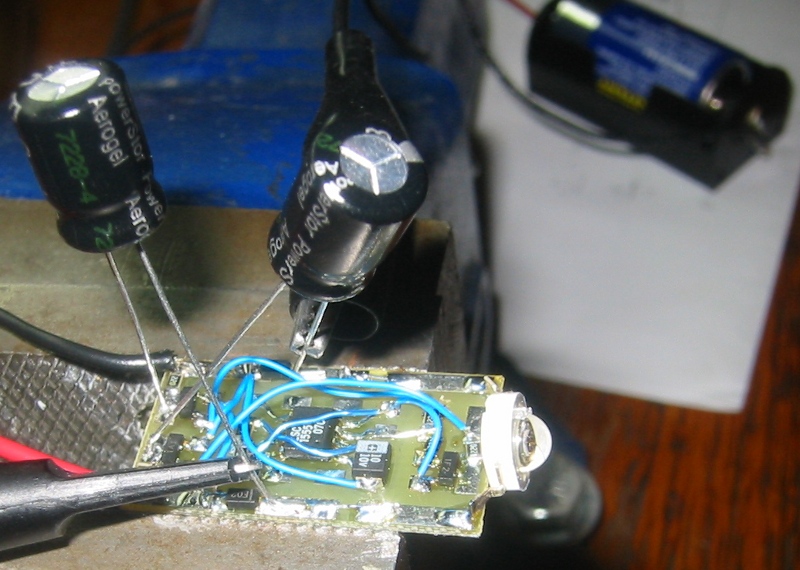

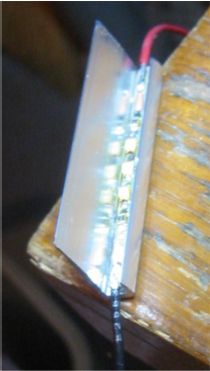

I designed a single sided board to mount on the traditional bicycle

water bottle cage mount (5mm bolts, 65mm spacing). The assembled board

looked like this:

The gEDA

files: Schematic

Layout

The design files: Gerbers

Postscript

PDF

Most of the board was done with 0.5mm lines and spaces with 0.35mm

lines and spaces where needed. As a result it should be realizable

with the toner transfer method. Here are the mirrored copper layer

images. Note that the board is 79.75mm by 19mm.

Mirrored copper: Postscript

PDF

I sent my board out to get

made. Here

are the files I sent. The company

was Olimex. You

have to edit the readme.txt file before you send these files off to

Olimex. This approach gets you 10 boards.

Pretty much any super/ultra cap will work here as long as the internal

resistance (ESR) is reasonably low. Higher ESR means less charging

current and a dimmer flash. Adjusting the value of the charging

resistors (R5, R7, R9, R10) downward can be used to compensate. Keep

in mind that increasing ESR is the major failure mode for supercaps

over time so you normally are better off starting with a low

value. Pretty much any 1 Watt LED will work as long as the forward

voltage is in the neighbourhood of 2.5V . The transistors are special

in that they must be capable of switching 1-2A with a low saturation

voltage.

Here is a parts list:

2 ZXTN25020DFLTA NPN low sat volt pulse transistor sot-23 (diodes inc)

2 ZXTP25020DFLTA PNP low sat volt pulse transistor sot-23 (diodes inc)

1 ZSCT1555N8TA low volt 555 timer so-8 (diodes inc)

3 MBRX120LF 1A Schottky Diode sod-123 (Micro Commercial)

1 C0805C105K8RACTU ceramic cap 1uf +-10% x7r 0805 (kemet)

3 ESHSR-0003C0-002R7 3F .09ohm supercap 3.5mm lead spacing (nesscap)

1 LTPL-P011A 1W amber led (Lite-On)

1 LTPL-P011R 1W red led (Lite-On)

1 2173 steel C cell holder (keystone)

These part numbers were findable

on Digi-Key at the time of this

post. Normally you do not get things like 1 Watt LEDs from an

electronic distributor like Digi-Key. You can usually get better prices

elsewhere for small quantities. I just wanted to show an example of

the LEDs I ended up using.

Here is what I did for mounting:

I suppose I could be accused of flaunting my geekiness here. I mostly

do stuff like this to attract the groupies. Social aspects aside, if

you live in a more hostile and/or corrosive atmosphere than I do you

might want to do a bit more with the enclosure ... such as actually

having one I mean. There is no switch, the battery is removed (or just

moved) when the flasher is not in use. If the bike is locked up

outside the battery ends up in a pocket. Any time the bike is in use

the battery is in place. That is just where I keep it.

The silicone sealant seen in the picture is intended to dampen the

vibrations of the capacitors to prevent lead breakage.

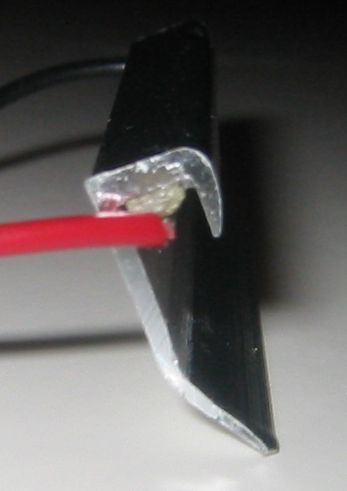

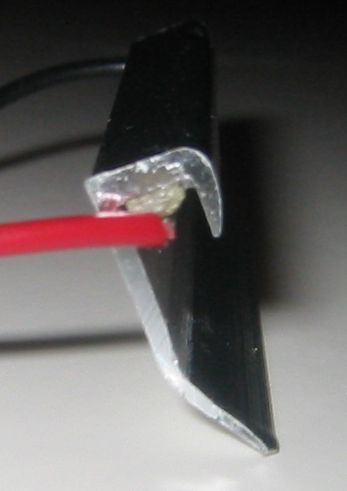

Here is what I did to mount the red LED on the rear:

This is attached low on the read fender. This demonstrates an

advantage to centralized electronics I guess. You can put the actual

light emitters pretty much anywhere. The overhang was intended to make

a shade for people who are close to the back of the bike. It didn't

really work. It also protects the soft silicone lens of the LED. I was

told by a fairly LED adverse friend that the flashes were not that

bothersome. I think that is because the LED is mounted low to the

ground.

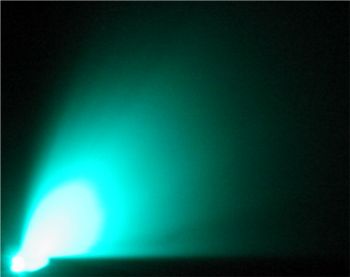

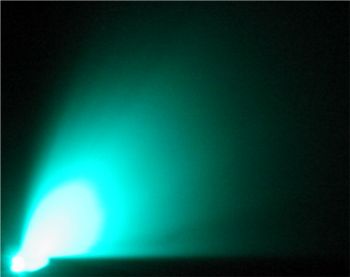

Here is what I did for the amber LED on the front:

This is mounted on the most forward extreme of the front

fender. Having a bright flashing light on the front of a bike is a bit

of a problem in that the rider has to be shielded from the flashes. I

made a reflector out of some shiny aluminium flashing in an attempt to

direct the light in line with the rider away to the front. It mostly

works but the top reflector directs some light onto the tire and the

road. Fortunately the tire is not all that reflective and the road

is far away. If I decide later that that light bothers me I will

blacken the offending part of the top reflector. Mounting the LED

relatively low like this produced an unexpected benefit. It greatly

reduced the flashing reflective sign effect.

These types of LEDs are often sold with a combination heat spreader

and terminal board. We don't need any sort of heat sink for this

application so I just soldered the bent up leads and glued the bare

LED in place with some silicone sealant. This flasher system is quite

insensitive to voltage drops in the wiring. Drops just make the

flashes a bit dimmer and the battery last a bit longer. As a result

I used 22 gauge wire to hook everything up.

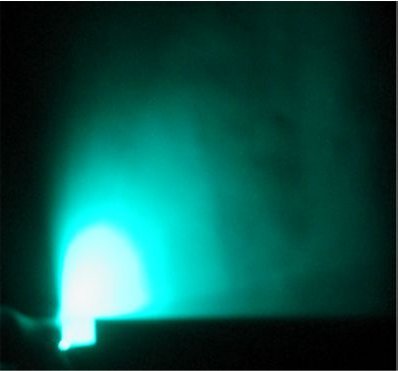

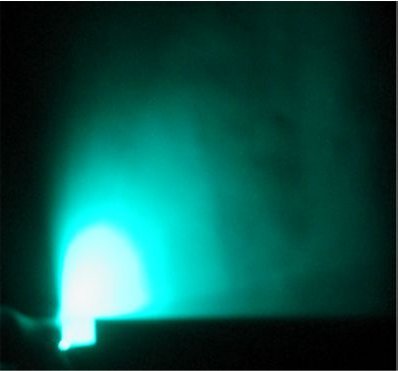

Here is the best I could do in terms of photographing the working flasher system:

For those that can relate; this was taken at F2.8 and ASA 400. This

shows a single flash. In terms of sending light in all possible

directions we are doing quite good. Too good really, a lot of

the light ends up either in space or on the ground. Better optics

could help here but those optics would have to be larger than what I

have now. Fortunately we have quite a lot of light available to waste.

Speaking of waste, you can adjust the brightness of the flashes by

adjusting the charging resistors (R5, R7, R9, R10). Reducing them to

15 ohms would get you up to into 0.9A pulse range. I am fairly certain

that the resulting system would be reliable. It would however drain

the battery more than twice as fast. I don't think it would really get

you any more attention (at least of the positive kind).

To speed up the flash rate you can reduce the value of R1. Halving the

value of R1 would get you a pulse rate of 2 per second and a flash

brightness of half at more or less the same battery consumption. The

brightness could be restored by halving the value of the charging

resistors (as mentioned in the previous paragraph) at the cost of

twice the battery drain.

Speaking of batteries, this system would work well with a NiMH

cell. In fact it would provide a more or less constant voltage/light

output over the useful battery life. A NiMH cell has a high current

capacity so a NiMH AA cell charged every week or so would likely be

optimal.

I looked up the local laws with respect to bicycle lighting to try to

determine if a front and back flasher system is legal. As far as I can

determine it is not. I don't think anything someone might actually use

for lighting in this century would be. It has been a long time since

the laws were updated. I guess I'll just have to live with the

uncertainty. Around here the only reason law enforcement does not

spontaneously do something like hand out a safety award when a

bicycle/rider combination is seen emitting light at night is because

they are afraid they might be up to something.

The other research inspired by this project was night time bicycle

safety in general. From my experience a bright flashing light on the

front of the bike pretty much eliminates the common case of collisions

caused by cars turning left across the path of the bike. The other

common collision occurs when a car pulls out of a side

street/driveway. I have often seen a driver glance in my direction

between the flashes before deciding to go. This could be expected to

reduce the problem to the fully stealthed bike/rider

case. Unfortunately there is a complication. At some point during the

manoeuvre the driver will see the next flash in their peripheral

vision. Then their behaviour becomes impossible to predict. One of

three things will happen:

- They will slam on the brakes.

- They will hit the accelerator.

- Those driving at the very edge of their ability will go into

overload mode. This will produce a situation where there is a

driverless car on the road for a time.

A constantly illuminated headlight would help with this so I have to

acknowledge that such a thing is still a good idea no matter how

bright my front flasher is. Having said that, I think that I will still

often find myself with just the flashers. History has shown that it is

too much to ask that I maintain much in the way of lighting over the

long term. I can however manage a single battery. That simplicity is

the greatest advantage of a system like this in my opinion.

posted at: 14:57 |

path: /ledlight |

permanent link to this entry

Wed, 04 Aug 2010

Once upon a time, someone invented a solid state light source called a

light emitting diode (LED). Sometime after that a company called

National Semiconductor created an integrated circuit (IC) called the

LM3909 that flashed a LED.

The LM3909 was considered a very exciting thing in spite of the fact

that flashing a LED was pretty much all the LM3909 did. It did not

produce particularly bright flashes. It did not even flash the LED all

that quickly. It would however flash a LED for a very long time (years)

from a single 1.5V cell. That was enough.

This was something new in the world. The LM3909 showed how profoundly

different a light source the LED was compared to everything that had

come before. People that did electronics for fun absolutely loved the

LM3909 for providing this insight. At one time you could buy a LM3909

in pretty much any large shopping mall in North America (the ones

containing a store called Radio Shack). Combining a LM3909, a

capacitor and a battery just to watch a LED flash is something that

pretty much everyone of my generation with an interest in electronics

has done at one time or another.

The LM3909 did something sort of clever. A voltage of 1.5V was not

enough to cause one of the red LEDs of the day to emit light. The

LM3909 would charge up a several hundred uF capacitor to a significant

fraction of the 1.5V battery voltage. It would then force the

capacitor to be in series with the 1.5V power source causing the LED

to light until the capacitor discharged. The capacitor was charged

through a couple of resistors that drew relatively large currents when

the capacitor was forced into series mode. To get reasonable

efficiency the resistor values had to be on the larger side which

limited the flash rate to something like once a second.

In the late 90's, I was enduring an entire team of people who were

attempting to teach me undergraduate engineering math. This caused me

to yearn for the life I had left behind (electronics). Due to the

nature of the Electrical Engineering program I got to take my bicycle

home in the dark fairly often. Once a woman in a van pulled over and

told me a story with a very unhappy ending. It was about her friend

who shared with me a love of stealthy bicycle travel. My thoughts

naturally turned to lighting. Lighting involving electronics pretty

much leaves some sort of LED flasher.

At various points during the ensuing project people would make the

helpful suggestion that I could in fact just buy a bike

flasher. I suppose those same people would suggest that a Jedi Master

could hop into the land speeder and go pick up a light sabre. I didn't

want just a bike flasher. I wanted the bike flasher. ... and

well, the LM3909 was not it. It was power efficient at the cost of a

very weak flash. I was sort of disappointed.

I still wanted to be able to use a single 1.5V cell so I used the idea

of using a capacitor as a voltage multiplier as seen with the

LM3909. I found that a 1000uf capacitor made for a reasonable flash. I

wanted to use 3 LEDs with good lenses (10mm) adjusted to produce a fan

of light directed down the road and somewhat to the sides. I just did

not have enough light available that I could waste it. I eventually

ended up with a single large power transistor switching individual

1000 uF capacitors for each LED. That was 3 amber LEDs and 3

capacitors on the front of the bike and 3 red LEDs and 3 capacitors on

the back. I had to look to find some sort of convenient oscillator

that would run on 1.5V (really 1V). Turned out that the LM3909 was

ideal for the job and was used as the timing source. Sometimes you

just can't avoid using the LM3909.

The flasher system was quite bright and was visible even on cloudy

days. It served me well up to the point that the bicycle it was

attached to was stolen from outside a post-university workplace. There

was no on-off switch, I simply put a C cell in a battery holder on the

bike frame. The battery life was pretty much perpetual. I didn't

really care if I forgot and left the battery installed. I could have

used a smaller/lighter power source but I do not like having to think

about changing batteries.

We now draw a bit nearer to the actual point of this post... While

investigating the present state of high power LEDs for

a circadian

light fixture project I spent some time wondering what a flasher

using a high power LED would be like. I had felt limited by the amount

of current I could blast the LEDs of the late 90's with. I was pulsing

the LEDs with something like 100 mA. A 1W LED is rated for 350mA and

can be pulsed to .5A-1A. They are also more efficient at converting

electrical power to light. In particular I wanted a flasher bright

enough to be seen in a urban streetlight environment from all

directions.

I wanted to be able to retain the single C cell power source even if I

ended up with a lot less battery life. Now, it turns out that .04

seconds is a kind of sweet spot for flash duration when dealing with

human vision. For a given available optical energy, putting that

energy into a .04 second flash produces the greatest perceived

brightness. Doing the capacitor trick as before got me a capacitor

value of around 0.22 Farad for a reasonable .04 second flash. That is a

big capacitor. Fortunately there has been a recent technology

breakthrough in the form of what are often called supercapacitors. I

really needed .022 Farad with a low internal resistance

(ESR). Contemporary supercaps do not roll that way. I could get a much

larger value than I needed with a low ESR but that would make for a

really large pulse. In the end I was still able to use the supercap to

multiply the voltage of the battery but I had to do it a different way

than the venerable LM3909 did.

The LEDs I was pulsing way back when had a forward voltage drop of

around 2V. Typical high power LEDs are 2.5V for red and amber and 3.5V

for green and blue/white. OK, goodbye to green and blue/white

then. There is still a problem with red and amber. If we are only

doubling the voltage the battery can only discharge to 1.25V

(2*1.25V=2.5V). Dry cells are considered used up at about 1V. We are

losing half the battery life. OK then, hello second supercap. Now we

can triple the voltage. That does cause a pretty severe hit

in terms of efficiency. Since there are no inductors here all extra

voltage gets lost someplace in a resistance. The doubler has a maximum

possible efficiency of 2.5V/(2*1.5V)=0.83 and the tripler comes out at

2.5V/(3*1.5)=0.56. Still, 56% efficiency with twice the battery life

available is significantly better than 83%. We also need enough extra

room to charge the capacitors with resistors. So the tripler is the

way to go here. I will leave it as an exercise to come up with

something better using an inductor.

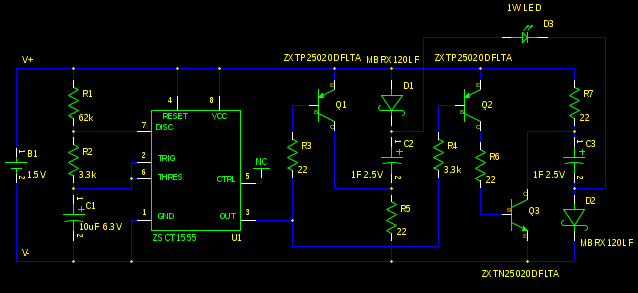

I still needed a timing source. The LM3909 is now discontinued (sniff)

but you can get 555 timers designed to run off of a single 1.5V

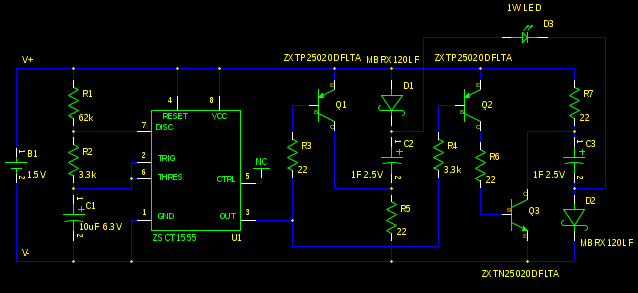

cell. I used the one from Zetex. Here is the schematic:

Here is a list of important parts used for the prototype (these were

the ones in stock at Digi-Key at the time of the order):

1 ZXTN25020DFLTA NPN low sat transistor sot-23

2 ZXTP25020DFLTA PNP low sat transistor sot-23

1 ZSCT1555N8TA lo volt 555 timer so-8

2 MBRX120LF 1A Schottky Diode sod-123

2 B0810-2R5105-R 1F supercap

1 LTPL-P011A 1W amber led

1 BHCL plastic C cell holder

1 9081CA so-8 proto board

U1 is just a 555 timer so I will not bother explaining how it works

here. The values of R1, R2 and C1 gave a pulse length of 0.06 seconds

and a period of 1.1 seconds with the prototype. Close enough I

guess. By the way, the Zetex data sheet for the part seemed actively

misleading. I had to figure out the timing (which is different from a

normal 555 timer) on my own. The circuit formed by D1,C2 and R5 is the

same thing as the circuit formed by R7, C3 and D2 (just turned over)

so I will mostly just discuss one of them. C3 is charged during the

non-pulse time through Schottky diode D2 and R7. The Schottky diode is

quite over specified here in terms of maximum current. I was looking

for a diode with low forward voltage at only 30mA. This one managed

about 0.2V. Note that capacitor C3 never gets charged up to 1.5V. It

only charges as much as is needed to fire the LED. That is because the

RC time constant of C3 and R7 is relatively long at 22ohm*1F=22

seconds. This time constant means that the flasher actually needs to

warm up over the course of 10 seconds or so before it reaches full

brightness.

The LED fires when pin 3 of U1 goes low. Q3 is turned on through Q2

and drags the positive end of C3 to the V- rail. D2 is reverse biased

and turns off. Let us assume that the V- rail is 0V. Then the negative

end of C3 (and the negative end of the LED) is now as little as

-1.5V. Q1 does the same sort of thing to C2 with respect to the V+

rail at +1.5V to drive the positive end of the LED as high as

+3V. Thus potentially the LED could have as much as 4.5V across

it. This would be too much voltage for the LED. The RC time constant

mentioned previously prevents this excessive voltage at the LED. There

simply isn't enough time for R7 to change the voltage of the capacitor

any significant amount before the next pulse. Eventually an

equilibrium is reached with the amount of charge going into the

capacitor during charging time coming out during the LED pulse

time. In practise the voltage across the capacitors is exactly enough

to add together with the battery voltage to make up the LED

voltage. It tends to be higher than expected because of the internal

resistance of the capacitors when the led fires. The capacitors are

rated at .4 ohms internal resistance and showed a drop of 0.2V with a

0.5A pulse. Lower internal resistance is better but makes for a more

expensive supercapacitor.

And speaking of things that drop voltage, the transistors used here

are special in that they drop very little voltage when turned on. They

need to be driven hard to do this. For the old flasher I ended up

using a transistor in a huge TO-220 package. As these transistors come

in SOT-23 packages this ends up being a sort of technology improvement

as well.

The LED current here is limited quite accurately by the combination of

the value of R7 and the duty cycle of the pulse. This is possible due

to the large value of the supercapacitor and is a very nice

result. Unfortunately as the battery voltage drops the voltage across

R7 drops. That means that the LED gets dimmer over time. With the

prototype the combination of extra voltage available due to tripling

combined with the internal resistance of the capacitors produced a

situation where the LED brightness was still a bit more than a third

of the full voltage brightness when the battery hit 1V ("dead"). That

is also a nice result. This could be improved by finding a less

voltage sensitive way to charge the capacitors.

Here is what the prototype looked like:

With a new battery it produced pulses of about 0.5A. The light output

is really intense ... which is good. I think that battery life should

be something like 100 hours with a C cell and 150 hours with a D

cell. The front and back dual flasher I now hope to build should thus

get about 50 hours on a C cell.

This flasher suffers from a problem I refer to as the infinite battery

life syndrome. You often see bicycle flashers in the wild producing

barely perceptible light output. I think that is caused by a

combination of human perception and the characteristics of LEDs. As

the battery voltage gets closer and closer to the LED forward voltage

the current decreases and as a result the battery life

increases. Eventually the current gets down into the microamp range

but the LEDs are still showing light. Since people are really bad at

judging brightness there never comes a time where it is obvious that

the battery needs to be changed. Since this is safely critical

equipment I do not think this is good design. Presently the prototype

is happily producing 63 mA (0.07V across R5 while charging) pulses at

a battery voltage of 0.83V after running steady for a week and a half

and now seems fairly stable. I guess one could add a voltage detector

and do something on low battery voltage. I have no idea what this

something should be.

I know that 1 second period flashers are considered with some disdain

in some quarters. The issue is that it makes it difficult for

observers to infer the speed and direction of the bicycle. I can rebut

this from experience as I have used such a flasher for some years. On

a totally dark street there might be an issue but in an urban

environment if you can draw attention to yourself there is almost

always enough light to follow the path of the bicycle/rider

afterwards. This is especially true if the bicycle is liberally

plastered with reflective tape as mine is. Since attracting attention

is important it seems reasonable to throw out as much light energy as

possible during the pulse. The best way to do this is to pulse as

infrequently as is practical.

The stuff about the pulse energy brings up another objection. Some

people feel that very bright flashers are obnoxious. The amount of

light intensity produced by my prototype during the pulse is more or

less the same as the light intensity produced for a much longer time

by the flash of a automotive signal light. The reason it is annoying

is because the light comes from a very small area. The problem is that

it is impossible to separate annoying from attention attracting. One

implies the other. From my interest in circadian light I know that

even very bright red LEDs can only zap one photoreceptor (amber is

pretty much one and a half). There are three types left so I do not

think it is possible to night blind someone with red/amber LEDs. So

given that, the concise response is:

Annoying? Good! I wanna live...

posted at: 21:39 |

path: /ledlight |

permanent link to this entry

Mon, 26 Apr 2010

The small area of LED light emitters makes it somewhat challenging to

use them effectively in low level lighting applications. The light is

hard to shade and diffuse efficiently. In the past I have used light

coloured ceilings and walls as diffuse reflectors. This works fairly

well but it can be a problem avoiding a bright area on the

wall/ceiling where the light is

mounted.

Here

is a description of a light I built that physically moves the light

emitters away from the wall to deal with this issue. This works but

the resulting fixture is quite large.

The ideal angle of the wedge of light from a wall mounted fixture is

something a bit under 90 degrees. We want to avoid illuminating the

wall behind the fixture while preventing people from seeing the small

bright emitters directly. We also do not want a lot of light on the

ceiling closest to the fixture as this tends to make a bright spot,

particularly if the fixture is close to the ceiling. The raw LED chip

itself emits light from a flat surface. This means that the light

distribution tends to be proportional to the cosine of the angle from

the normal. Cutting this distribution in half would produce a fairly

good light distribution for the application. That could be done by

adding a horizontal reflector. Since we have no need for optics other

than the reflector we might as well use surface mount LEDs and make

the fixture small.

I wanted to experiment with monochrome light as we are targeting night

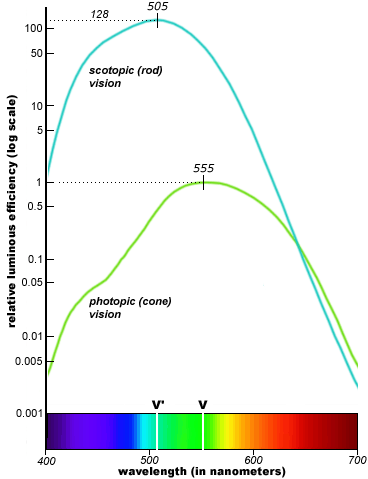

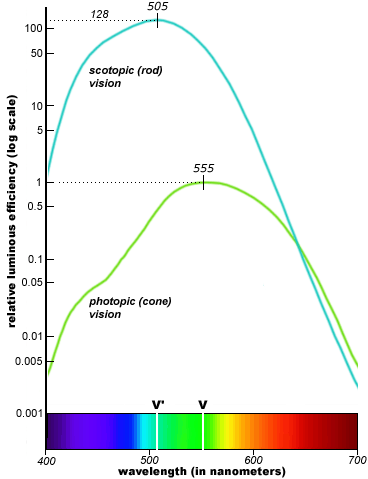

vision here. This plot:

from here

suggests that the best wavelength for night (scotopic) vision would be

505 nm. That by coincidence is the wavelength that is perceived as the

North American traffic signal "green" colour. As a result LEDs that

emit this odd wavelength are relatively easy to find. The colour ends

up being sort of a cyanish green. Light with a wavelength of 505 nm is

fairly active

as circadian

light but the light levels achieved here are much too low to be

disruptive.

My thinking up to this point inspired me to go out and

buy these

from here. I ended up with the larger

1206 packages because the supplier I ordered from would only provide

the wavelength I wanted in that size. The extra width (1.6mm) ended up

not being a problem and they were easier to handle than the 0805

packages I normally prefer for hand made surface mount based

prototypes.

I spent some time planning to use a thin sheet of stainless steel as a

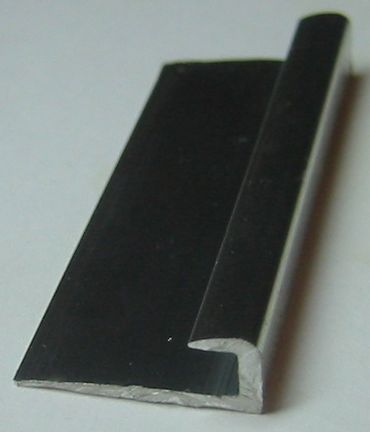

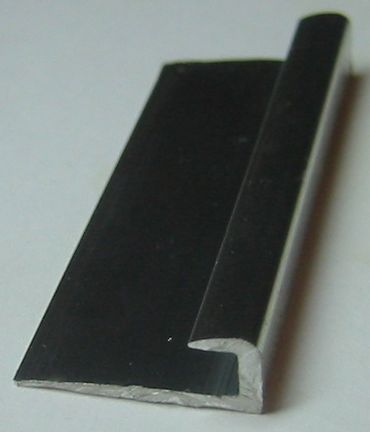

reflector until I stumbled on this at a local home improvement store:

It was originally intended as an edging for a counter top. It was made

out of a shiny alloy and was close to the desired shape. It comes with

a prefabricated wall shade in the form of the overhang.

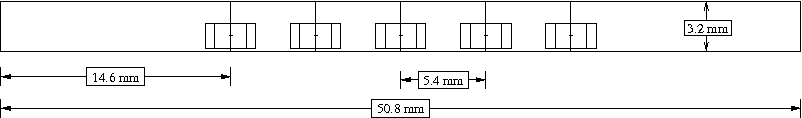

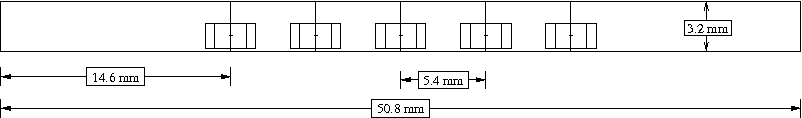

The use of the surface mount devices pretty much mandated the use of the PCB. Rather than measure anything I made a drawing at 5X scale:

and then printed it at 20% to use as a guide. Much to my surprise the Xfig program on Linux got it exactly right with no fiddling. That's not all that expected for a mere figure creation program. Here is the drawing in various formats:

fig,

postscript,

pdf,

svg,

png.

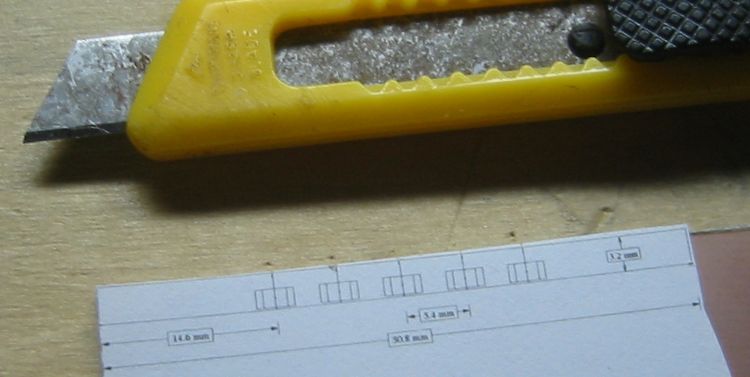

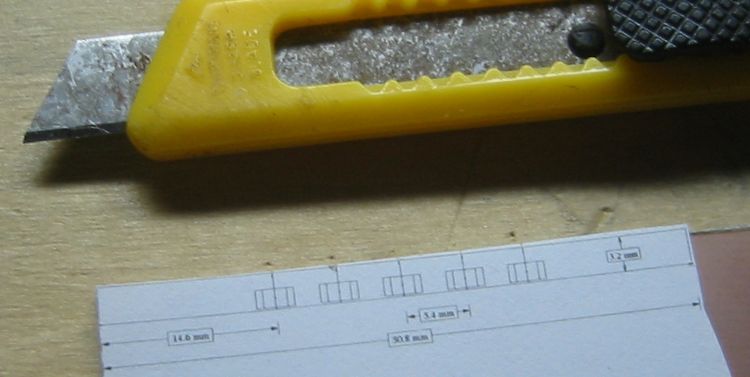

A sharp tool was used to transfer the dimensions from the 1X scale drawing to the copper:

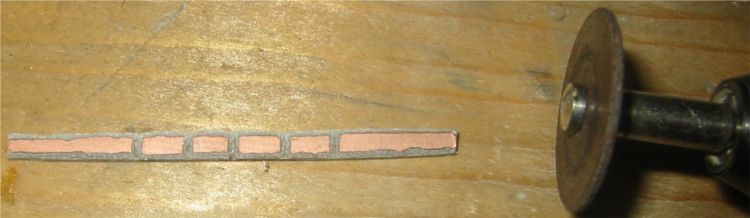

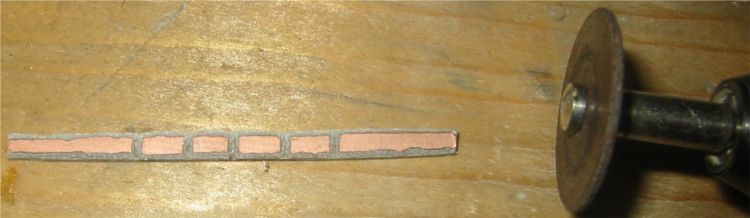

followed by a layout:

followed by some use of a cutting disk:

Note that the edges of the copper have been ground off to prevent

shorts through the metal reflector. I just dragged the cutting disk

along the sides. A more appropriate tool would make for a straighter

edge.

I first applied liquid flux to the PCB. This is probably optional for

such a simple assembly but I had it available and it did make things

easier. A popular method of hand soldering surface mount devices starts

by adding solder to just one pad. In my case this meant I would first

add solder to each alternate area of copper like this:

Then the device is moved into position and held in place with

something like a round toothpick. Heat from a soldering iron is

applied to the solder (but not directly to the device) to sweat solder

the device in place. Then it is fairly easy to solder the other

pins. Once the device is well secured the original pin can have solder

added if needed. This was the scene after soldering was complete:

I have ended up with 3 LEDs and 2 resistors. When I made the drawing I

was enough of an engineer to want to cover the case where 4 LEDs were

required to make up the voltage. The idea was to just skip one cut for

the 3 LED case. When I made the board I was apparently enough of a

technician to be compelled to make things as shown on the

drawing. Thus I managed to make a classic error involving an ambiguous

drawing in a way that normally requires two people. Using 2 resistors

solved the problem in the assembly phase which meant I had also

achieved pointless symmetry which is another sort of classic

error. There is probably some insightful observation on the human

condition available to me here but it escapes me.

I picked a LED current of half the normal specification based on the

hope that it might increase the lifetime of the fixture. I have no

idea if that makes sense with LEDs. Heat might not be an issue. LED

manufacturers like to quote a lifetime of 100,000 hours (11 years)

which really just means they think their product might last a long

time. With a target current of 10 mA we end up with

(12V-(3.2V*3))/0.01A = 240 ohms of resistance. I ended up using two

110 ohm resistors.

After soldering the wire connections and cleaning off the rosin based

flux with pure isopropyl alcohol I was done with the electrical

assembly:

I used a small amount of RTV silicone sealant to glue the board in

place in the reflector. The board would not stay where it was supposed

to go. I ended up using the weight of the wires to keep it in place:

The preceding image shows that the reflector is quite a lot wider

than would be required just to reflect the light from the LEDs. The

idea was to prevent light from escaping from the ends of the channel

without any extra fabrication. This worked but the channel itself was

still a bit bright where it could be seen on the ends.

Testing the light distribution against a white surface showed some problems:

To prevent light from projecting below the horizontal plane the

assembly had to be tilted back towards the LED side. This is

inconvenient for the eventual installation of the fixture and caused

two other problems. The largest amount of light was going more or less

directly up to the ceiling above the fixture creating a bright

spot. The other problem was that a significant amount of light was

finding its way to the wall directly behind the fixture which created

another bright area. Blackening the top of the channel helped but I

eventually took a different approach and bent the end of the reflector

up like this:

The edge of the reflector is bent up enough to be in the same plane as

the top of the channel. This means that there is no light projected

below the horizontal plane when the fixture is sitting flat against a

horizontal surface. The result was:

This is much better. I consider the design complete.

Next I'll go into the various thoughts and observations that came out

of this activity...

When using monochromatic light even illumination can create a

situation that destroys visual information. The light from the

designed fixture is very uniform. Evenly illuminating large areas of

the ceiling results in a situation related to an

outdoors whiteout

condition. Objects are still visible but with little detail. I suspect

that this would only be an issue in rooms small enough to allow a

single fixture to evenly illuminate the entire ceiling. A fix is to

move the fixture closer to the ceiling to produce sharper shadows at

the cost of a more intense hot spot.

The Homo sapiens sapiens set depend on visual transitions in their

peripheral vision to help with things like walking around. The sharp

vertical light transition produced by the reflector means that a

strong cue should exist for orientation and balance. This artificial

horizon effect might end up being the more important visual

information. This system is after all intended to improve

navigation. I am not sure how well this actually works at low light

levels. There is probably a research opportunity here.

An important performance feature of a low level lighting system is the

length of time it takes for vision to adapt enough to navigate after

the high level lighting is turned off. Testing this produced a result

that initially seemed odd. It seemed that the nighttime vision system

(rod based) was adapting significantly faster than the daytime vision

system (cone based). I would see a monochrome image before I could perceive

the colour of the light. This lag was something like 5 seconds. The

oddness here came from the impression that nighttime vision takes a

much longer time to adapt to darkness than daytime vision. Some

research revealed that this isn't really true in general. It turns out

that the traditional way to check the time it takes people to adapt to

the dark is to expose them to really bright light for a long time and

then plunge them into complete darkness. This presumably is to

simulate the common situation where one is walking along in a sunlit

meadow before falling into a fast moving underground river. In more

reasonable transitions from light to dark it is the nighttime vision

that kicks in first

(Ref, See

Figure 2). At the light levels I am using the effect would be close to

the maximum. The daytime vision system has to adapt to a level close

to the daytime minimum while the nighttime vision system only has to

adapt to a light level 100 times higher than the nighttime

minimum. The transition is driven harder for the nighttime

system. This I think strengthens the contention that 505 nm is the

magic wavelength for low level lighting.

Since the edge of the reflector is to be bent up it might make sense

to cut the reflector in such a way as to allow the bent up part to

shade the bright ends of the channel. In other words, the reflector

could be cut off at an angle to make the LED side shorter than the

bent side. This could also hide associated wiring.

Light fixtures that point upward accumulate dirt. This creates a

maintenance issue. For some applications it might be better to put the

light sources below eye level pointing downward. Hallways and

walkways are sometimes lit this way.

Blue LEDs at 470 nm are fairly effective for nighttime vision but are

a lot less visible to daytime vision than 505 nm LEDs. This might make

blue LEDs preferable where it is important for the night lighting to

be invisible during the day.

The next step is to make some of these and deploy them around the

house to try out the low level lighting lifestyle for myself. I should

be able to hide the fixtures on the top of door and window

frames. This will make it possible to hook the wires up into the attic

for an easy installation. I will report on the results when and if

there are any.

EDIT: proceeding -> preceding

posted at: 15:49 |

path: /ledlight |

permanent link to this entry

Thu, 18 Feb 2010

I seem to be stuck on the low level lighting thing. An advantage to

not working is not having anyone to tell me to get back to work...

Here is an

approachable introduction to modern colour vision theory. It helped me

a lot. The rest of the site (watercolours) is a bit too technical for

me but I think I now know what to expect when I mix single colour

LEDs.

For my bathroom night light I now think that just green and red LEDs

would of worked fairly well. I could of balanced them to give some

sort of yellow. A problem would occur if the colour was exactly the

same as the perceived light colour. It would not be visible against

white. The 3rd colour in between removes that ambiguity. That is

assuming that the green and red LEDs do not balance out to the in

between colour. The apparently excessively bright green LED is thus a

feature as it moves the balance point well away from the yellow LED

wavelength.

Another possible problem with just using green and red (or blue and

red) is that you would end up with more green light. Green (and blue)

can blind night vision when not used in moderation. I now think of my

bathroom night light as primarily yellow with a bit of some other

wavelengths thown in to allow some colour discrimination.

posted at: 17:13 |

path: /ledlight |

permanent link to this entry

Wed, 27 Jan 2010

Some wisdom came out of my night light projects. I'll share that here.

Are light emitting diodes ready for prime time residential lighting?

That question is surprisingly controversial. I am not really sure

myself about the answer to the general question. I am sure that

for low level lighting LEDs entirely rule.

Up to this point in the history of the world there has not been a

practical and efficient way to make a small amount of light for a long

time. Incandescents are particularly

bad

for efficiency and life.

Electroluminescent

were the closest thing pre-LED era but they are an area emitter and

are thus hard to shade effectively. They also need high voltage

wiring.

The result of this is that the system of vision intended to allow

people to function at night is not really used by most people. People

can see at levels down to 0.01 lux. Typical residential living spaces

are lit to levels between 50 to 100 lux. That is as much as 4 orders

of magnitude more than the absolute minimum required.

It may be that we have hit a technological threshold. If low level

lighting is more practical then perhaps it will become more common. It

is interesting to consider how a hypothetical low level lighting

enthusiast would arrange the lighting in a house.

Let us first invent a specification. All living areas should be lit to

the level of moonlight on a clear night. One

source claims this is

.3-1 lux. Brighter would interfere with things like sleep. Darker

would mean a longish time to adapt after turning off a light. Tropical

moonlight would be a bit bright I think so let's aim for the lower end

of .3 lux.

For a 3m X 3m room we would have around 10m2 to illuminate. Lux is

lumens per square metre so to hit .3 lux we would need 3 lumens. LEDs

with an efficacy of 30 lumens/watt are available so our power budget

could assume around 0.1W per lamp. Since this is mostly best case I'll

double the assumption to 0.2W. It would likely take 7 of these lamps

to light my house. So the total power draw is 1.4W giving us a yearly

power consumption of 12 kW/h. That would cost me $0.72CAN a year.

The fixtures could be built in at time of construction. Retrofit would

be easy as you would only have to snake in something like alarm wire

to power the lights. The lights could be designed to run off the door

bell transformer. If instead you ran them off a small sealed lead acid

battery charged from a wall wart you could claim that you had

established a sort of residential emergency egress lighting system.

The proposed level of lighting would of course mostly serve for

navigating through the house. This would still simplify things. Most

rooms would not need any ceiling lights and associated

switches/wiring. Hallways and stairways would not need three way

switched lights.

In general safety would be greater at night. I used to fall over the

stool in my kitchen on a semi-regular basis before I installed my

always-on counter light. I did get quite good at it but it would be

unrealistic to think I would not eventually do it badly. The compact

fluorescent that lights my basement stairs sometimes likes to wait just

long enough for me to miss the top step before producing light after I

turn it on. A little bit of light would help there too.

Our house of the future would probably need some built in higher level

lighting. A ceiling mounted light for the dining room table is

nice. Vanity lighting for the bathroom mirror is essential to allow

the residents to maximize their apparent reproductive fitness. Kitchen

counters and the stove would need bright lighting. Pretty much the

rest of the lighting inside the house would be provided with lamps.

When one deals with lighting one is dealing with some fairly primal

stuff. I always need to turn on the main light in the bathroom before

having a bath. I think I am afraid to go in the dark water. Perhaps at

some level I am afraid of alligators. When fluorescent lighting become

popular people immediately started illuminating work spaces to some

almost insane levels. Legend has it that photographers of that era

used to have trouble believing the result of their light meter

readings. They were seeing outside daylight levels of lighting inside

buildings. A decade or so later "de-lamping" became popular when it

became fashionable to care about power consumption. My point is that

people like it when it is bright indoors and the brighter the

better. Perhaps low level lighting as a way of life will never become

popular simply because of that.

Here are some interesting/related links;

posted at: 22:37 |

path: /ledlight |

permanent link to this entry

Powered by PyBlosxom